Project Introduction

Petro Exir Kangan Pentane Production Project

Objectives, Rationale, and Requirements of the project

Isopentane, as one of the most important derivatives of pentane, is widely used in insoluble compounds due to its high volatility and strong tendency to evaporate. Its competitive price compared to alternative products, superior chemical properties, and growing demand in consumer industries have driven significant growth in the global market for this product. According to forecasts, the pentane market value is expected to increase from $95.3 million in 2016 to over $173.9 million by 2026, reflecting an approximate annual growth rate of 6.6%. Studies also indicate that Asian markets have substantial export potential, and producing this product can create new opportunities for international market expansion and development.

Technical Review of the Project

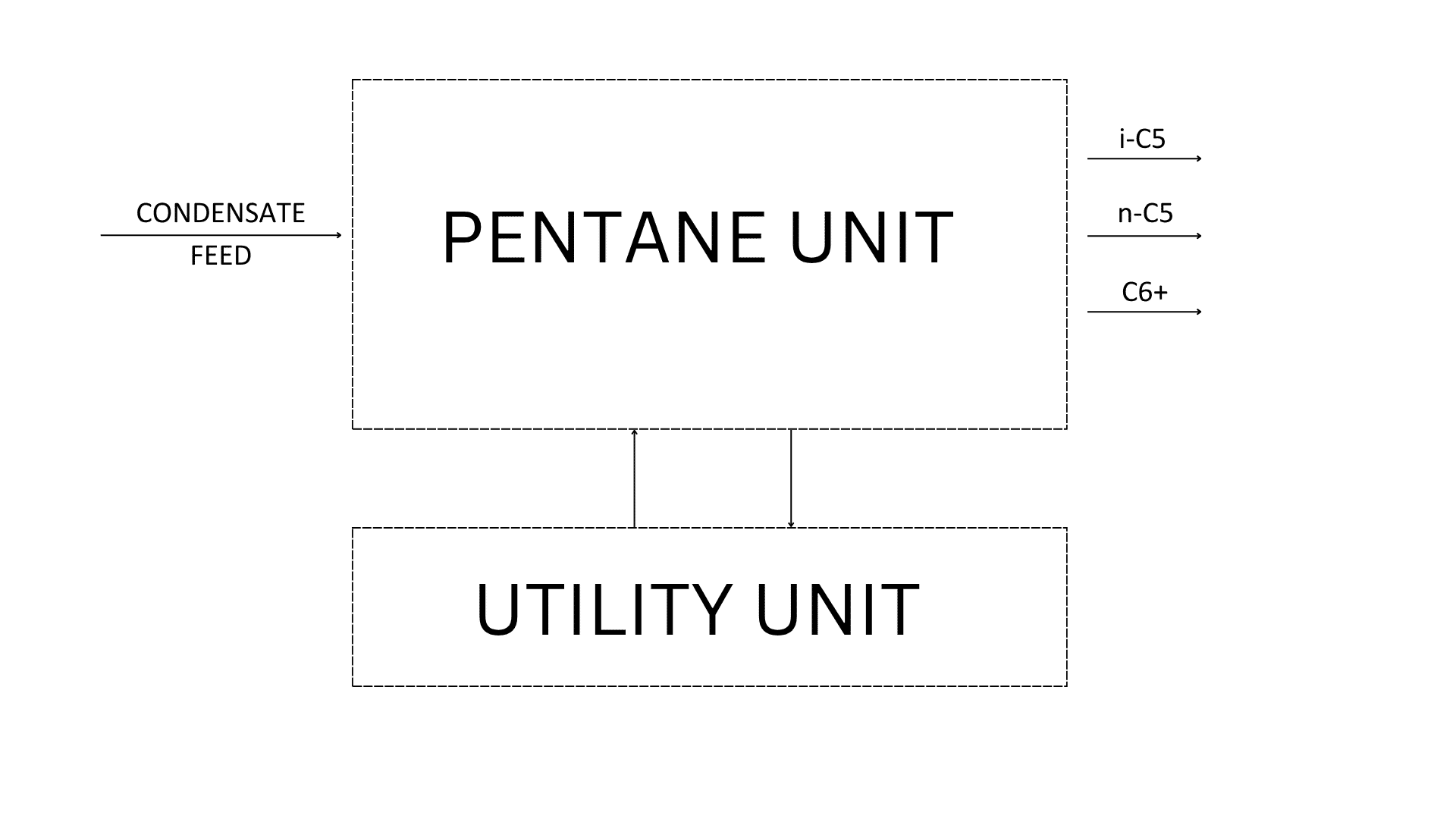

The Petro Exir Kangan Pentane Solvent Production Project is being developed on a 7-hectare site in Kangan County, Bushehr Province, approximately 600 meters north of South Pars Phases 22 and 23.

For the implementation of this project, the required feedstock, which consists of gas condensates, will be transported from the Kangan Petrorefinery Unit (located about 9 km from the site) via tankers and stored in dedicated storage tanks. The feedstock will then be pumped and pressurized into the desulfurization unit to initiate the production process.

The annual feedstock requirement for this unit is estimated at approximately 80,000 tons.

Gas condensates with high sulfur content, along with a liquid oxidizer, are first introduced into a mixing reactor using hydrodynamic cavitation technology, where sulfur compounds are oxidized into sulfones and/or sulfoxides. The mixture is then separated in a decanter, isolating the liquid phase from the gas phase. Following this step, the oxidized sulfur compounds are removed using an absorber (or solvent).

The caustic washing process is capable of removing light mercaptan compounds, while the removal of heavy mercaptan compounds is more challenging using this method. The feedstock is first washed with caustic solution in the caustic washing unit and within the towers.

One of the common and commercially established methods for absorbing sulfur compounds is the use of absorption towers. When the sulfur compounds are light and present in low concentrations, this method can be particularly effective in reducing sulfur content.

In this process, the feed containing sulfur is initially fed into three parallel towers, where the absorption process takes place. Once a tower reaches saturation, its inlet valve is closed, and the three towers are rotated through a regeneration cycle.